Lens Materials

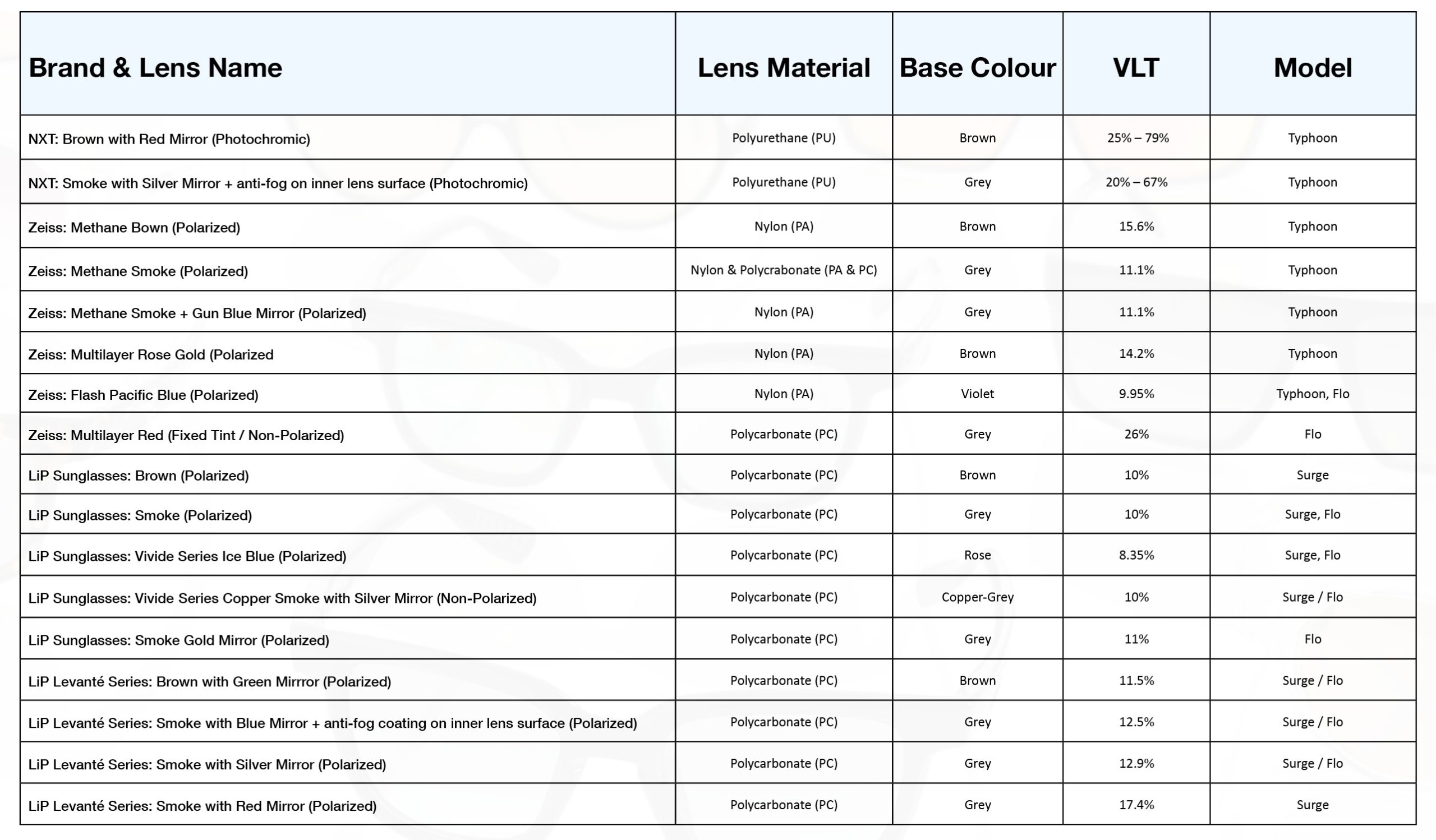

Below we summarise the differences between polycarbonate and nylon material.

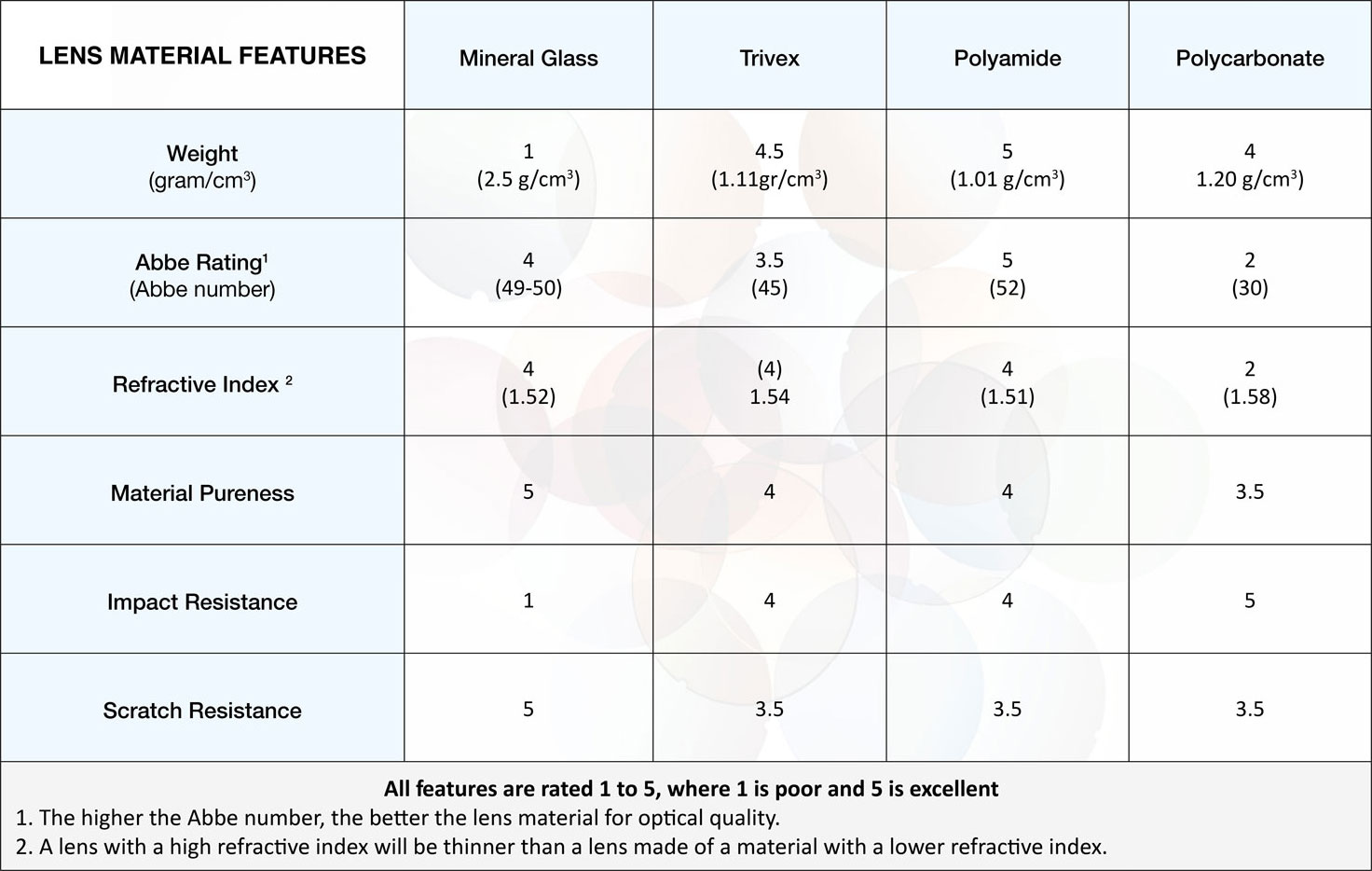

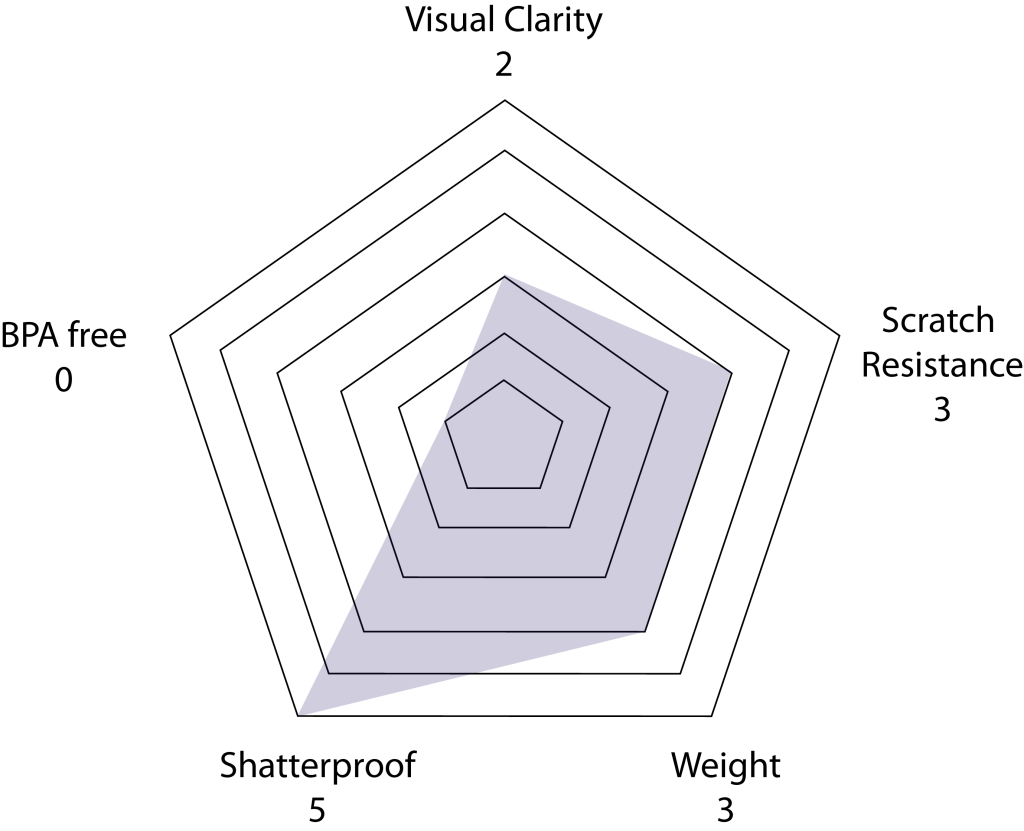

Polycarbonate

Polycarbonate has been the lens material of choice for action sports for decades for good reason. To this day, it retains the top spot for impact resistance and shatterproof qualities, so this material is highly suited to impact sports like kitesurfing and wakeboarding.

It is a lightweight lens material with a weight of 1.20g/cm³

The scratch resistance of polycarbonate material is medium.

The refractive index of polycarbonate is 1.58

The Abbe value is 30.

Each lens material has its own characteristics. We measure 5 key lens characteristics on a scale of 1 – 5, with 5 being the best and 1 the poorest.

• Visual Clarity •

• Scratch Resistance •

• Weight •

• Impact resistance •

• BPA rating •

Each measure is not necessarily equal in importance. They are there as reference points to allow you to consider which of the lenses is suited to you and your needs.

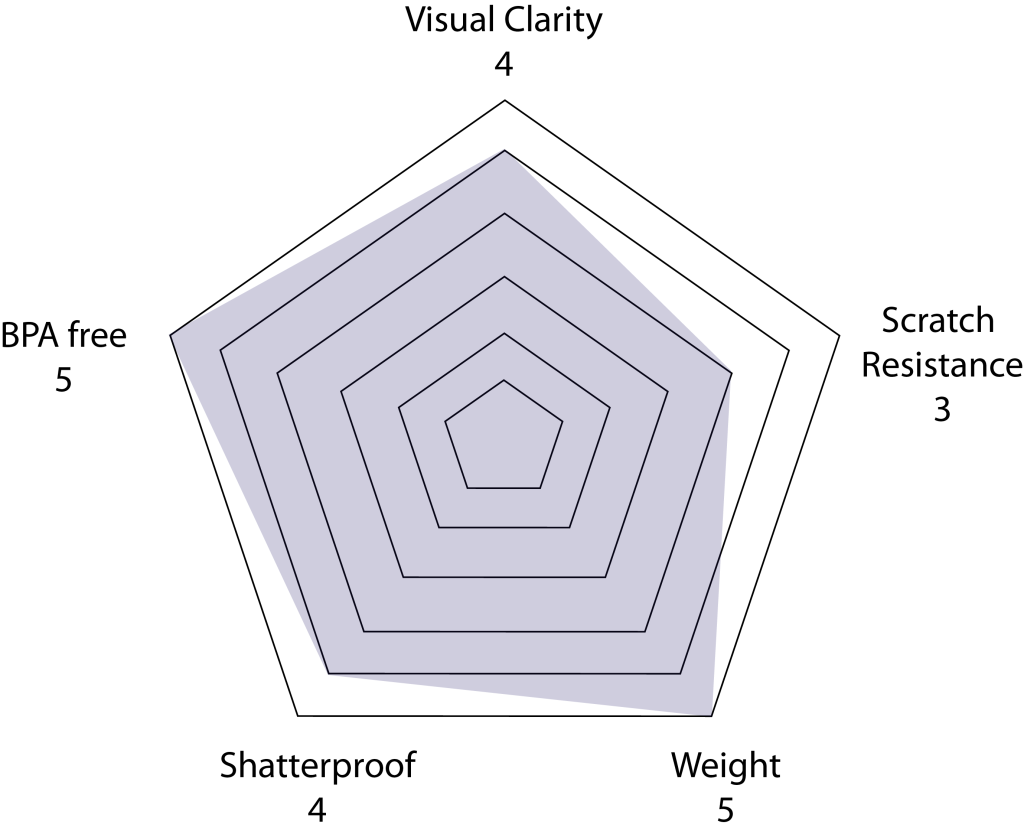

Nylon

Nylon offers enhanced clarity, lighter weight and better environmental credentials than polycarbonate. The one measure on which nylon is eclipsed by polycarbonate is impact resistance, but marginally so.

Super-lightweight lens material with a weight of 1.01g/cm³

The scratch resistance of nylon material is medium.

The refractive index of nylon is 1.51

The Abbe value is 52

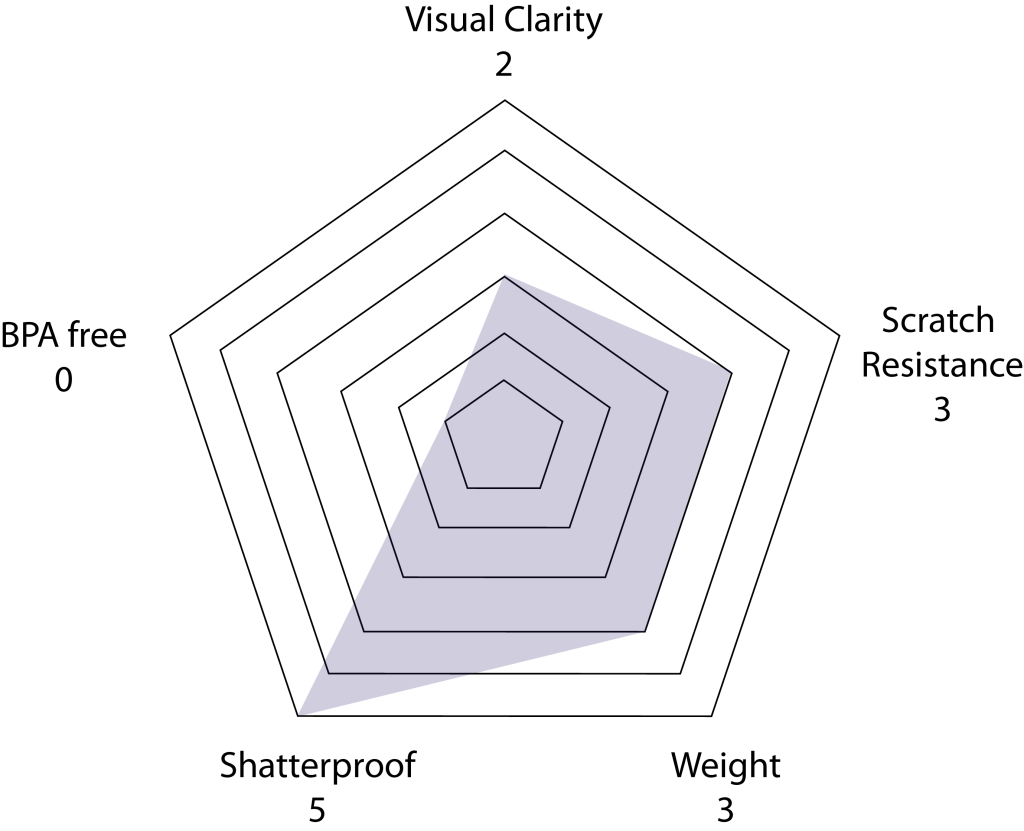

Polycarbonate

Polycarbonate has been the lens material of choice for action sports for decades for good reason. To this day, it retains the top spot for impact resistance and shatterproof qualities, so this material is highly suited to impact sports like kitesurfing and wakeboarding.

It is a lightweight lens material with a weight of 1.20g/cm³

The scratch resistance of polycarbonate material is medium.

The refractive index of polycarbonate is 1.58

The Abbe value is 30.

Each lens material has its own characteristics. We measure 5 key lens characteristics on a scale of 1 – 5, with 5 being the best and 1 the poorest.

• Visual Clarity •

• Scratch Resistance •

• Weight •

• Impact resistance •

• BPA rating •

Each measure is not necessarily equal in importance. They are there as reference points to allow you to consider which of the lenses is suited to you and your needs.

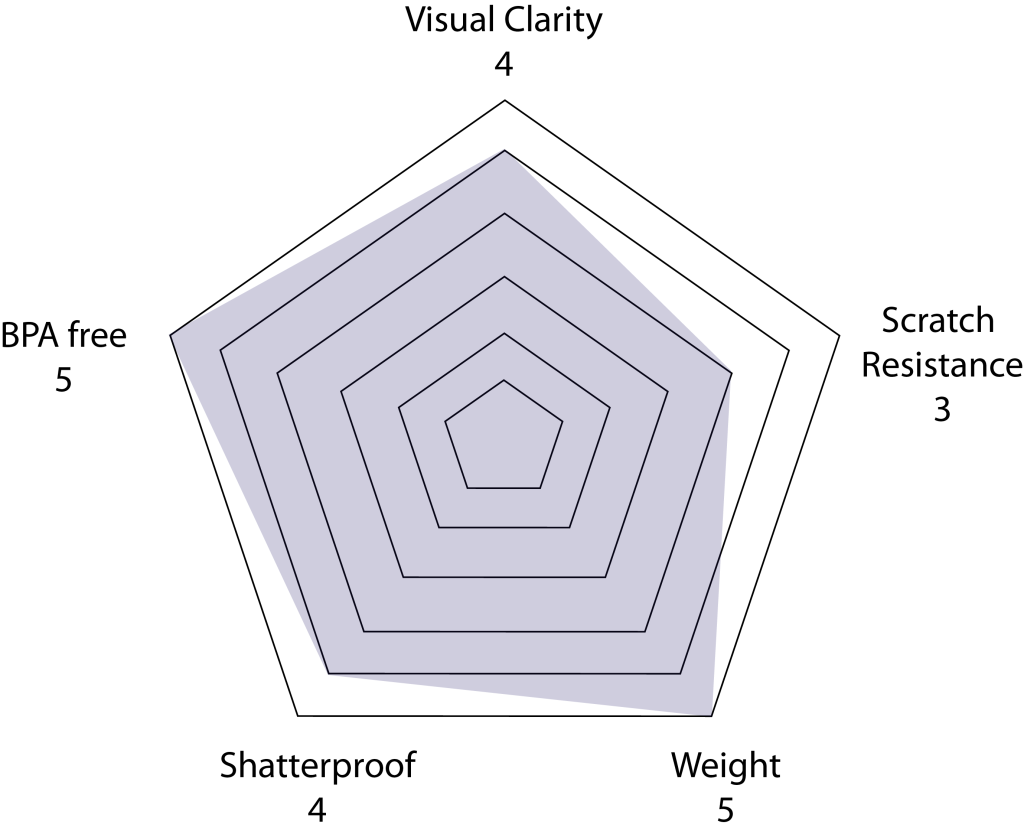

Nylon

Nylon offers enhanced clarity, lighter weight and better environmental credentials than polycarbonate. The one measure on which nylon is eclipsed by polycarbonate is impact resistance, but marginally so.

Super-lightweight lens material with a weight of 1.01g/cm³

The scratch resistance of nylon material is medium.

The refractive index of nylon is 1.51

The Abbe value is 52